Meeting your equipment needs from Agitators to ZHE’s.

WELCOME TO ASSOCIATED DESIGN & MANUFACTURING

Phipps & Bird is proud to add the Associated Design and Manufacturing product line to its corporate family. AD&M, founded in Northern Virginia in 1965, is a leading manufacturer of US EPA-approved TCLP equipment used for evaluating hazardous components found in solid and liquid wastes. AD&M designed and developed the Zero Head space Extractor (ZHE), used along with the AD&M Rotary Agitator in performing the Toxicity Characteristic Leaching Procedure (TCLP).

AD&M’s environmental analysis products join Phipps & Bird’s water and waste water treatment plant laboratory equipment. All products are manufactured at Phipps & Bird’s production facility located in the Historic Scott’s Addition of Richmond, Virginia. And, like Phipps & Bird, AD&M products enjoy a world-wide reputation for quality, durability and reliability.

AD&M’s precision contract manufacturing services continue to be offered to customers with unique manufacturing requirements. Visit the Contract Manufacturing tab for additional details.

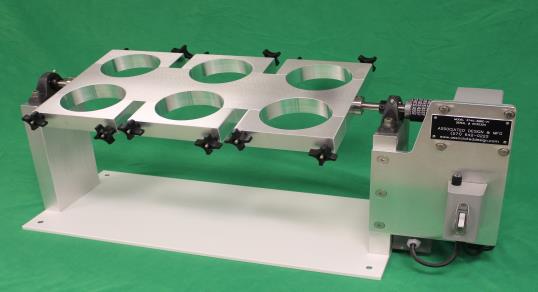

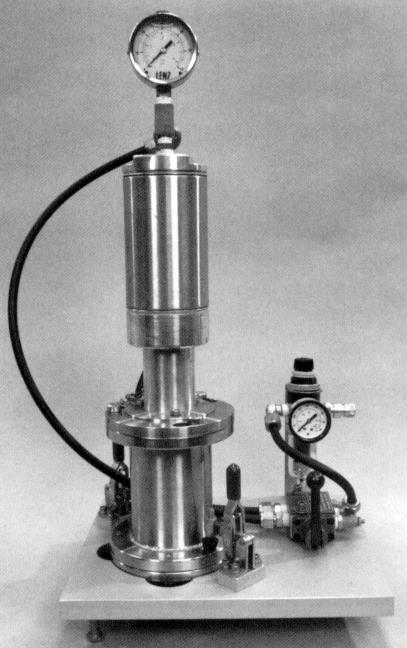

Model #AD3745-ZHE Request Information |

The Model AD3745-ZHE Zero Headspace Extractor is an extractor vessel used for separating solid samples and their volatile extracts during the Toxicity Characteristic Leaching Procedure (TCLP) U.S. EPA Method 1311 and the Synthetic Precipitation Leaching Procedure (SPLP) US EPA Method 1312. The AD3745-ZHE permits the sealed extraction and pressure filtration of volatile pollutants without losses due to evaporation.

Complies with US EPA Specifications Design Features Built for Durability and Convenience No Tools Required Proven and Approved |

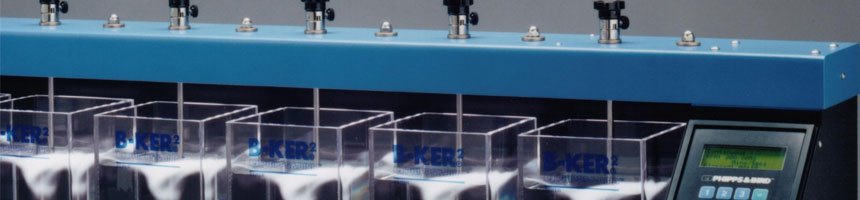

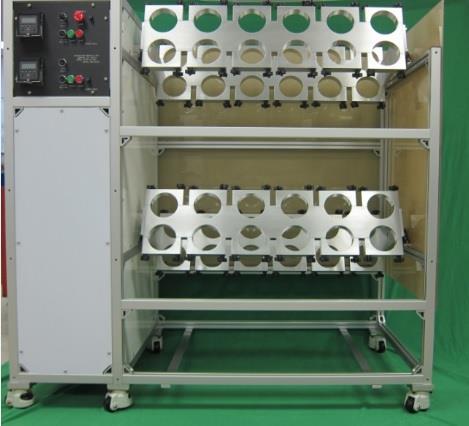

ROTARY AGITATORS

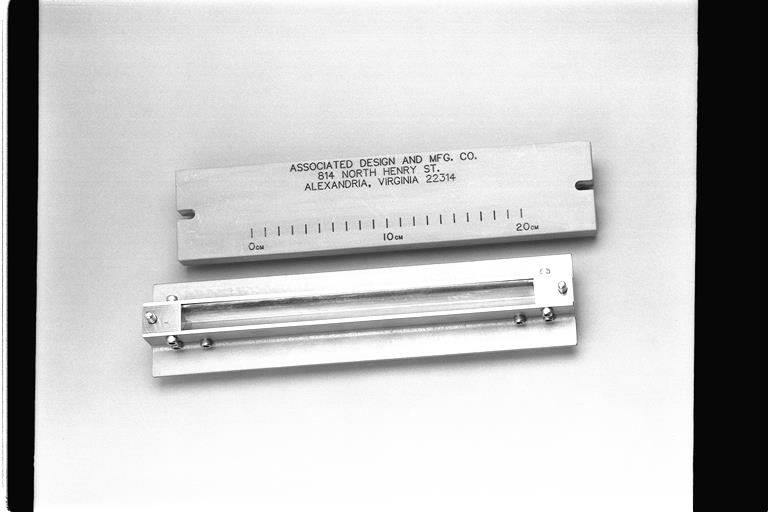

** denote model-specific identification numbers  ** denote model-specific identification numbers Download catalog for full line of products here |

The Associated Design Rotary Agitators are sample agitation devices developed for use during the Extraction Procedure, Toxicity (Ep-tox) US EPA Method 1310, Toxicity Characteristic Leaching Procedure (TCLP) US EPA Method 1311 and the Synthetic Precipitation Leaching Procedure (SPL) USEPA Method 1312.

Complies with US EPA Procedures Built for Durability and Performance |

Burn Mold

Download the catalog for further details (page 16) |

The Associated Design Hazardous Waste Filtration Units are pressure filtration units used for separating solid samples and their extracts:

Design Features No Tools Required Proven and Approved |

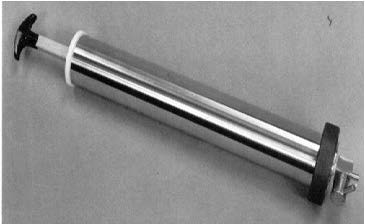

STAINLESS STEEL GAS TIGHT SYRINGE

|

The Associated Design Model AD3790-GTS Gas Tight Syringe was developed to collect the filtrate and transfer extraction buffers for the analysis of volatile leachates during the Toxicity Characteristic Leaching Procedure (TCLP) U.S. EPA Method 1311 and the Synthetic Precipitation Leaching Procedure (SPLP) U.S. EPA Method 1312.

The gas-tight syringe is a useful accessory for the AD3745-ZHE and AD3740-ZHE Zero Headspace Extractors by Complies with USEPA Specifications Facilitates Filtrate Collection Built for Durability and Convenience No Tools Required Options Proven and Tested |

LIQUID RELEASE TEST DEVICES

|

The Associated Design Model AD3760-LRT Liquid Release Test Device is a laboratory or field unit designed to perform the proposed Liquid Release Test (U.S. EPA Method 9096) on sorbent materials used inside hazardous waste containers.

Complies with USEPA Specifications Design Features Convenient Sample Loading No False Releases Field or Laboratory Use Proven and Tested |